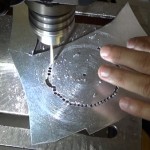

For part two on scratch building a Radar Eye, you will need to find a way to cut out the circle for the Radar Eye. The first method I tried did not work, so I had to go to plan B. This involved cutting small circles around an etched circular line on the sheet metal. I drilled all the holes around the sheet metal and for the slot.Watch Full Movie Online Streaming Online and Download

Once this is complete, I used a Dremel to cut the gaps out so I was left with an empty circle, and I did the same thing for the slot. I was careful not to go to fast or I could cut parts I wanted to leave. A smaller sanding disc is recommended if one is available.

The following steps will smooth out the edges along the inside of the circle and the slot. Use a sanding wheel and go around the edges to make it look pretty. You may have to draw another circle around the eye to make sure you still keep the form.

Watch Part III for learning how to bond the seams together.