The top of the R2D2 dome has a dome washer around a dome topper. The method I used to get the washer was to take a 1″ x 1/4″ washer with the same thickness as the dome, and use a step down bit to widen the hole. This was a careful process until I was able to get it just right.

Craft Spheres Made Into Holoprojectors Part II.

In Part I, I built the ball section of the Holoprojector, and in this part I will show you how I constructed the cowel section of the Holoprojector. It requires a bit of patience and some interesting tools. The hardest part is to find the center of the sphere. Here is the same video as in the previous post, were we left off at the 4:34 mark.

You will need a set of friction dividers to do this with my method. There are 4 large holes to be drilled through the backside of the sphere to get the proper dimensions of the Holoprojector. Although these are a bit bigger than spec, noone will really notice anything.

The first step is to find the center of the sphere and make marks 1/4″ in 4 quadrants. To make sure the marks are in the right spot, use the friction dividers spaced out at 23/64″ and draw semi circles to until they make an “x” on each of the spots marked.

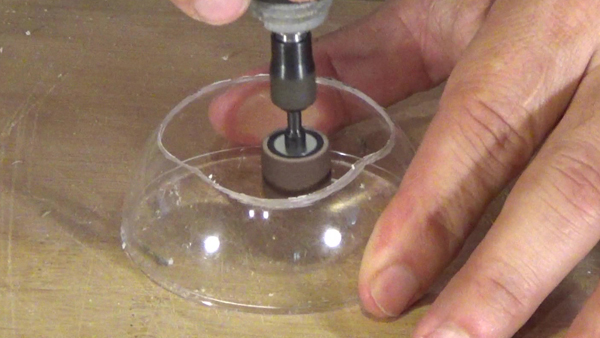

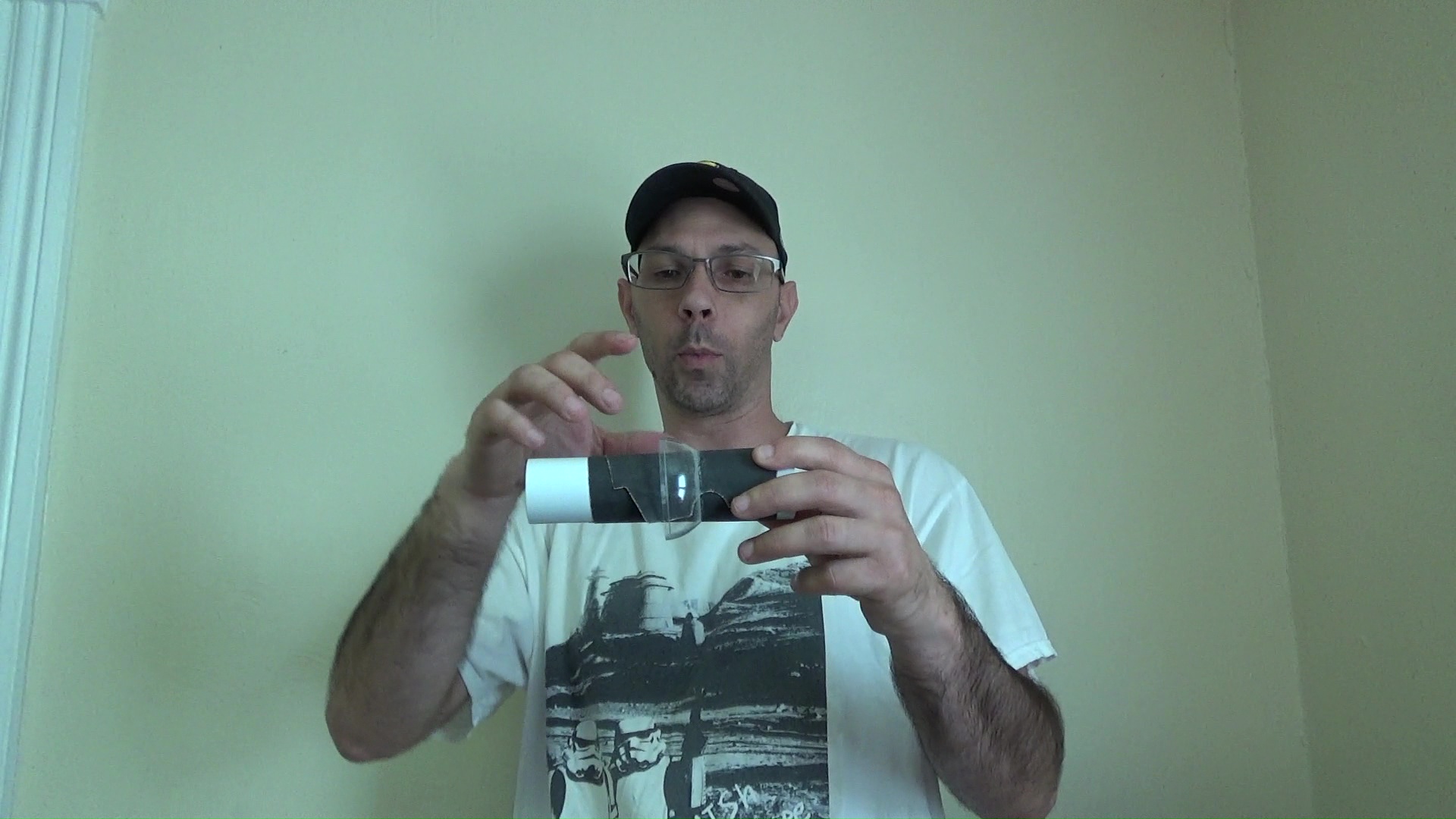

Once the pilot holes are drilled, we enlarge them slowly with bigger bits. A 1-1/2″ hole saw is used on the concave side of the sphere with pilot bit that fits the hole saw. Slowly drill through this and don’t hurt your hand doing so. Do this for all 4 holes.

After it punches through, two raised portions must be made flat as the originals only have two flat spots. Once flattened, the inside is sanded smooth and everything can be assembled and painted how you like. It might be easier to paint after it is assembled. If you are making static Holoprojectors, gluing first is a better option.

Based on if you want the Holo to move or not will determine how you put them together. I have two static and one on a servo with an up/down motion. Each will need to be assembled differently.

Up next is the final assembly with lights, mounting and a servo.

Craft Spheres Made Into Holoprojectors Part I.

To get the look of Holoprojectors, a mouthwash cap was first turned into a Holoprojector cone. The next step is to get the spheres so you have a ball, inside of a ball. This is all achieved by the use of crafts spheres that can be made into holiday ornaments. Any craft store should sell these in one form or another, a total of 6 spheres is needed. 3 x 3-3/4″ and 3 x 2-3/8″ plus extras for when you mess up, and you will mess up!

Parts:

- 3 x 3-3/4″ sphere

- 3 x 2/3/8″ sphere

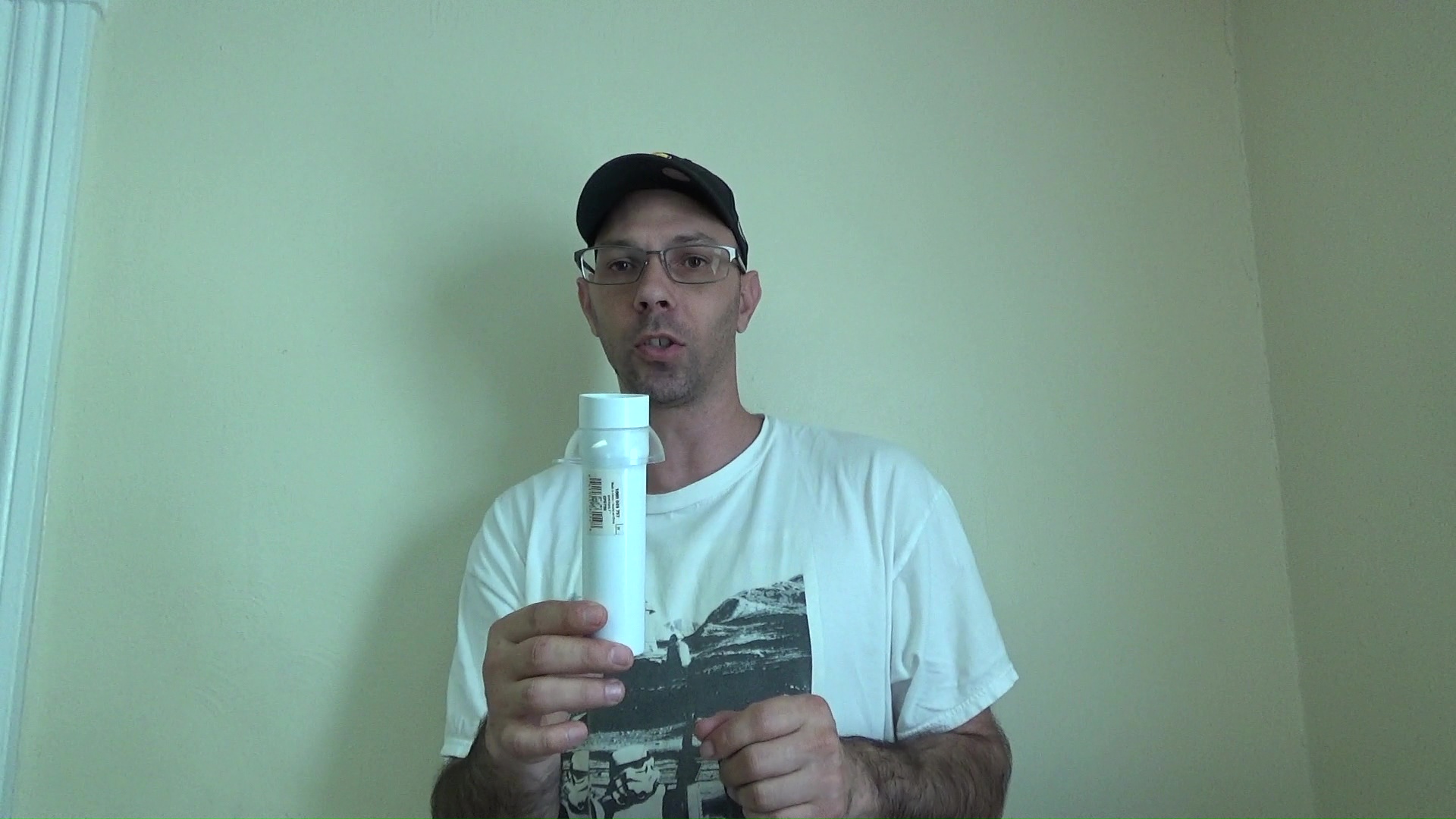

- 3 x 1-1/2″ PVC coupler that has a 1-5/8 dia on one end.

Below is an example of the type of craft spheres needed to make the Cowel and Ball joint. Most hobby craft stores will have this type, and is usually located by the holiday ornaments section.

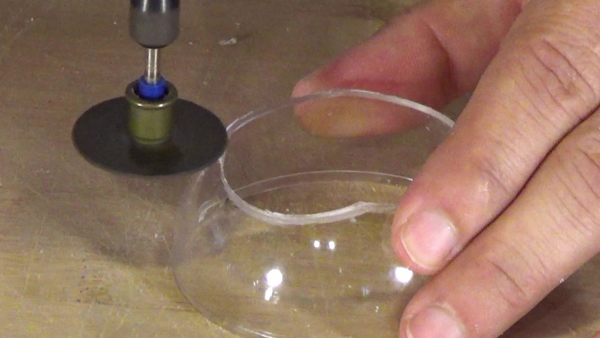

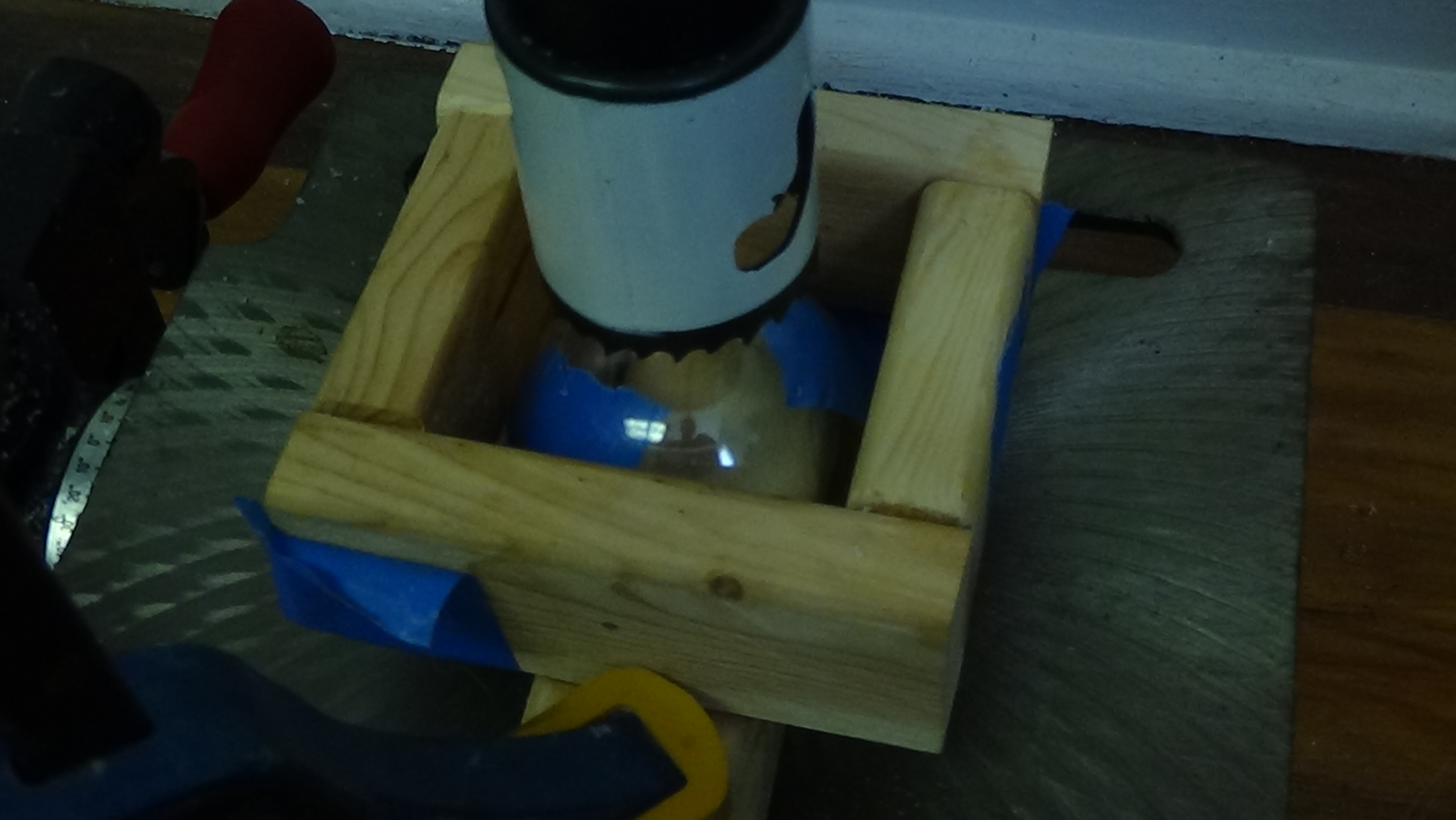

The next step is to cut holes in each of the spheres according to the dimensions on the blue prints for the Holoprojectors which are found on the Astromech.net forum. Lets start with the Ball section of the Holo, using the 2-3/8″ sphere. We will drill a 1-5/8″ hole through the top. I used a self made base to secure the sphere from moving.

I then used sandpaper around the beveled portion of the pvc pipe to sand the hole very carefully until I could get a snug fit around the PVC. Sand, and than test fit accordingly. Take into account the thickness of the sandpaper so you don’t over enlarge the hole.

The next step is to cut the PVC into three parts. The top part, the bevel, and the base. Each part will be used to hold the projector together and house the electronics.

Cut off the beveled portion below the end of the bevel by 1/32″. Cut the 1-5/8″ OD section off the bevel. Sand both ends smooth.

I glued the large end of the beveled piece into the cone I made from the mouth wash cap, securing it to the flat part made from the styrene strip from the previous post. After this, I glued the small end of the beveled piece into the large section of the PVC and placed a bead of putty around the edge.

This portion can than be inserted into the ball half and complete the first part of the ball and cowel.